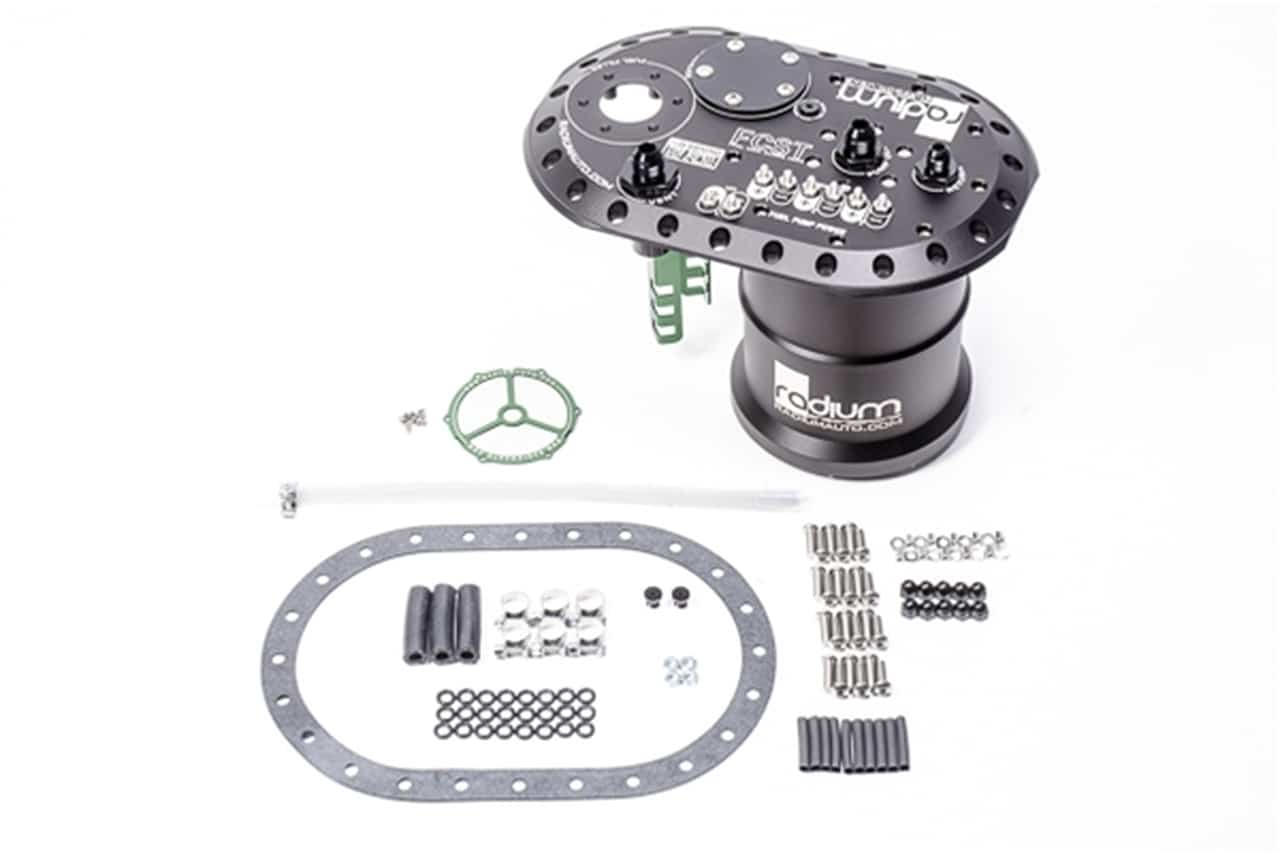

Radium – Radium FCST – Pumps Not Included – Walbro GSS342/AEM 50-1200

£786.79 ex VAT - £944.15 inc VAT

Since 2010, external Radium Engineering fuel surge tanks have been an excellent way to eliminate fuel starvation that occurs in racing.

Available on back-order

Radium FCST, Pumps Not Included, Walbro GSS342/AEM 50-1200

Since 2010, external Radium Engineering fuel surge tanks have been an excellent way to eliminate fuel starvation that occurs in racing. To simplify plumbing and packaging, in 2013 Radium Engineering introduced the first generation Fuel Cell Surge Tank (FCST) to the competition vehicle market. It quickly became the preferred fuel system for professional racing.

WHAT IS A FCST?

The Fuel Cell Surge Tank is a drop-in fuel pump system for Radium Engineering’s popular fuel cells or any cell that uses the industry standard 6×10 24-bolt fill plate bolt pattern. The FCST is designed to protect EFI vehicles that experience fuel starvation. It is NOT a glorified trap door box with baffles. It features a true dual-chamber fuel tank utilizing a single lift pump and up to 3 surge tank pumps all packaged inside the fuel cell. It provides all the benefits of a traditonal external fuel surge tank without safety concerns and plumbing complexity.

IS THIS COMPATIBLE WITH MY FUEL CELL?

To install a Radium Engineering FCST into a fuel cell, the following criteria must be met:

1. The cell must have the industry standard 6″x10″ 24-bolt flange opening.

2. The opening must be on the top face of the fuel cell (i.e. not a side face).

3. The cell depth must be at least 7.7″ (196mm) measured from the outer top face to the internal bottom face.

HOW IT WORKS

A lift pump scavenges fuel from the bottom of the fuel cell and pumps it into the 2 liter surge tank. Inside the surge tank canister, up to 3 EFI fuel pumps can be used to feed high pressure fuel to the engine. If the lift pump starves, the volume inside the surge tank canister will keep the surge tank pumps fed and the engine supplied with fuel. The return from the pressure regulator is also routed to the surge tank canister to help keep it full. An integrated 1-way fill valve always keeps at least as much fuel in the surge tank as what is outside in the fuel cell. Excess fuel in the surge tank simply overflows back into the fuel cell. This dynamic sequence is all done inside the safety of a fuel cell.

Features:

-Merged single 10AN ORB female threaded outlet. All pumps use check valves that prevent back-flow for multi-pump applications.

-One-way fill valve located on the bottom of the canister that allows fuel in, but not out, keeping the surge tank full.

-Multiple fuel pump options including gerotor, turbine, and brushless DC motor pumps.

-Hermetically sealed high-current stainless steel electrical studs capable of handling all pumps.

-Simplified servicing features eliminating nylon sealing washers and fuel cell retaining brackets.

-Full CNC aluminum construction with anodized surfacing for superior corrosion resistance.

-Fuel compatibility: leaded and unleaded gasoline, methanol, ethanol, E85, etc.

-Dynamic safety vent valve with rollover protection and fuel fill shut-off.

-Optional fuel surge tank level switch and diagnostic LED failsafe port

WHATS IN THE BOX?

The following comes standard with every FCST variation configured per part number

-8AN DSV (dynamic safety vent) valve

-6×10 24-hole FKM Viton gasket

-6AN male return fitting (other sizes can be utilized)

-8AN male pump out fitting (other sizes can be utilized)

-Fuel level sensor block-off plate

-Fuel level switch block-off plug

-Stainless steel mounting hardware

-Insulated anodized aluminum acorn nuts

-Electrical power wire ring terminals